-

.

I'm collecting ideas to plan the development of specialized versions of devWing and devFus for 3D printing.

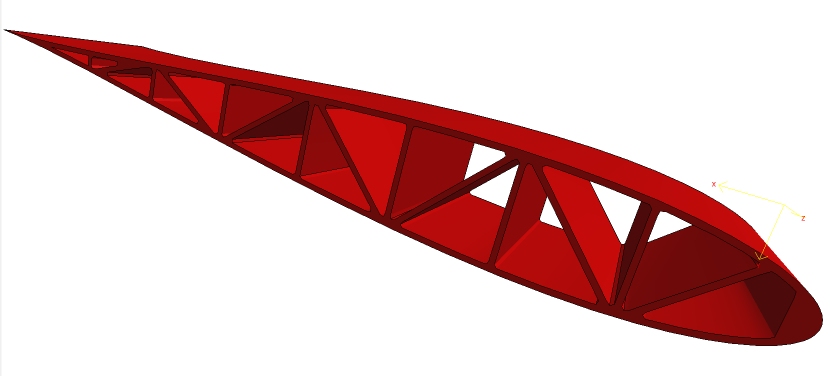

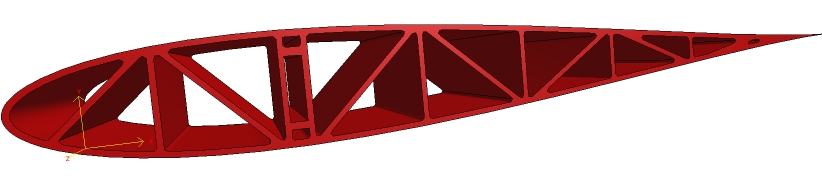

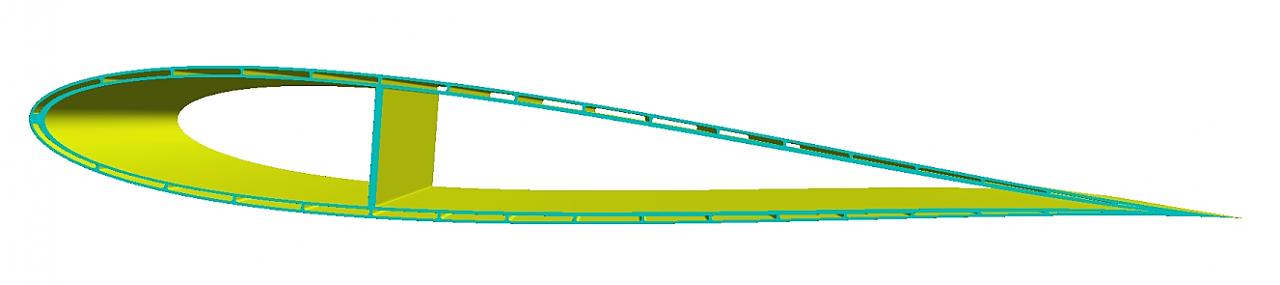

The basic idea is to use the actual technology of devWing and devFus to create Stl files of Blocks of wings and fuselages, with complex (honeycomb type or better, with optional inside spars) internal structures to optimize weight and strength.

Every part can then be 3D printed with the largest face placed on the board. Optional spars will help to glue the part aligned and to increase the strength.

Any idea, photo or message is here welcome, to define the best possible options for these applications.

I plan also to add to the actual devFus 3 and devWing 1 new features to create Stl files for their parts (ribs, formers, spars, decks and son on), so 3D printer owners could also create fuselages and wings based on formers and ribs using 3D printing, instead of cutting pieces from wood or other materials.. -

.

Some examples I realized to explain better what I mean by a single possible (basic) wing block:

.

. -

Chartman1.

User deleted

Printing 3D ribs like this sounds a good idea but what about bonding balsa sheeting to the ribs ? . -

.

The only problem with 3d printing is that most printers beds are too small to produce anything bigger than 250mm! unless they are printed in sections and joined together. .