-

-

|

.

|

| Guys

Here is my review and demonstration of the 5 axis "CNC Foam Cut" controller from Hobbild using a 32-bit Arduino Due. It's very impressive and works fantastic. The hot wire control is excellent.

Have a look and I'll be glad to answer any questions

https://youtu.be/eY21hR9O0i8

Keith |

|

-

|

.

|

| Hi Stefano

That's great news is there a time period for the trial.

Keith |

|

-

|

.

|

| Hi Jeff

Sorry, I set the first link to private. It should be fine now. The first video in the playlist is this one which may be more useful https://youtu.be/YuCkEB2kIkM |

|

-

-

-

|

.

|

| Have you set the current on the drivers to match your stepper motors. what stepper motors and drivers are you using?

keith |

|

-

|

.

|

| Hi

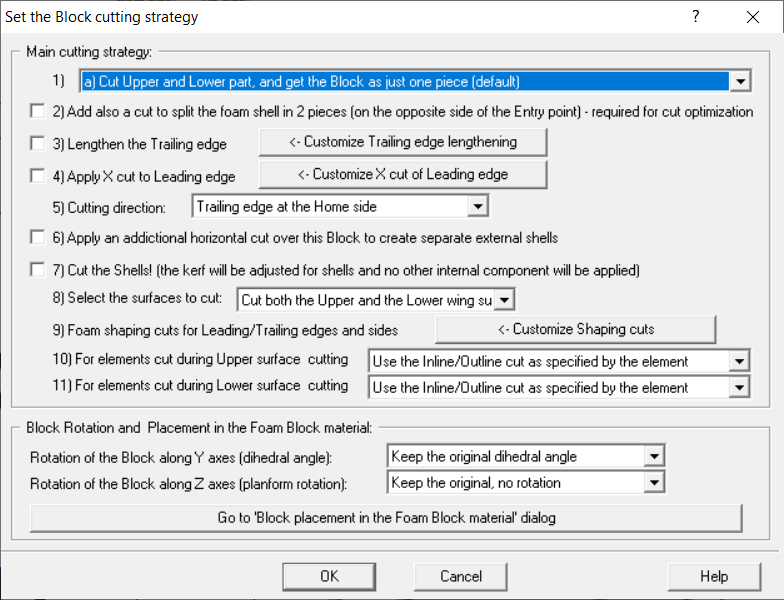

You could try in the cutting strategy option 5 Cutting Direction "trailing Edge at the Home Side"

That way it will exit at the trailing edge and hopefully not leave a mark.

I have mine set that way.

Keith |

|

-

|

.

|

| Looks very good. Now you can build some great models.

Keith |

|

-

|

.

|

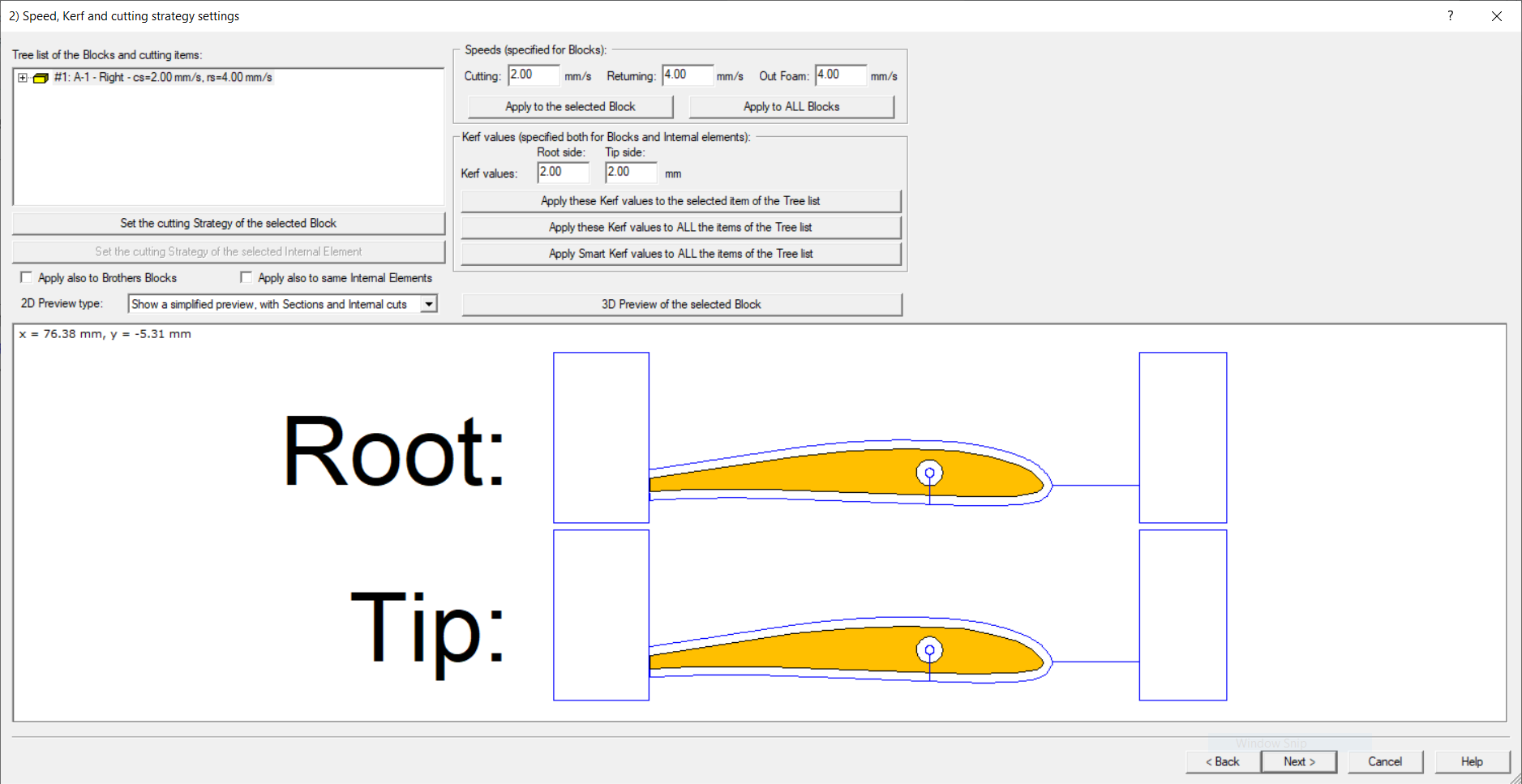

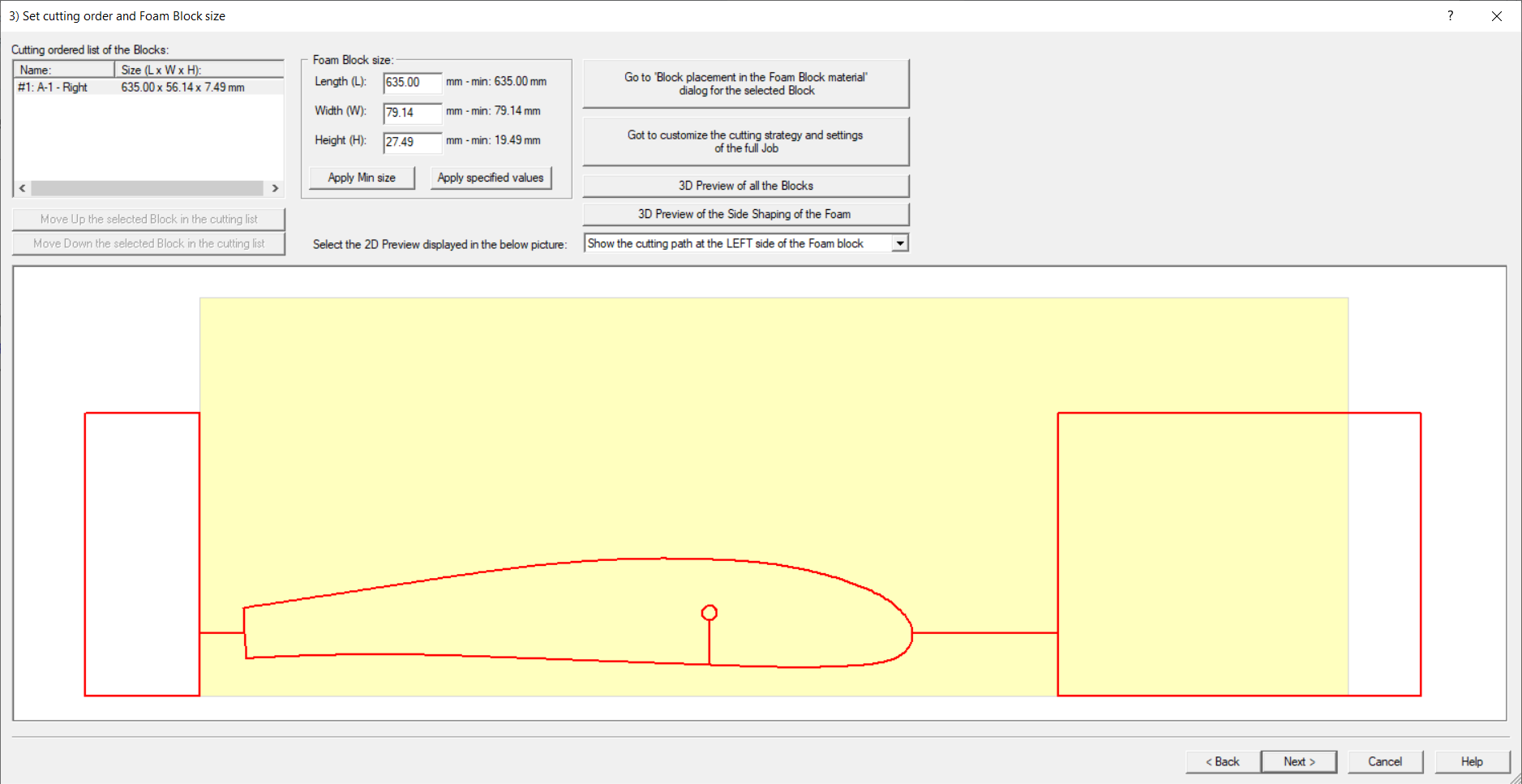

| Here's Part 3 showing how to

- Setting up the foam cutter

- Cutting the parts

- Cutting Root and Tip Angle

https://youtu.be/dL-SgkMmhzw

Thanks

Keith |

|

-

|

.

|

| Thank you.

I'm working on Part 3 now which will show the foam cutter making the wing parts. Going to use DevCNC Foam which I've just switched over to. I have limit switches working now which are useful for foam cutters.

It's taking a little longer than I expect to get the video made due to some family issues with my wife's elderly parents.

Keith |

|

-

-

|

.

|

| Hi

I have just uploaded a new video tutorial for the recently released DevWing Foam 2. The first video Part 1 covers the design phase and the new features in DevWing Foam 2. It's still good for the previous release.

Part 2 will show how to create the Cutting Projects and some exports and will be released as soon as I can. Part 3 and 4 will show how I cut the parts out and the maiden flight. https://youtu.be/pjx6_OrfhVQ

|

|

-

|

.

|

| Hi Stefano

Thank you that was it. I think I tried everything but this one.

Edited by keith howlette - 12/9/2019, 22:03 |

|

-

34 replies since 8/11/2013

.